At this time I am in development with the following

Development hardware:

- PIC32 (PIC32MX795F512L) USB Starter Kit II - DM320003-2 ($55.00)

- PIC32 I/O Expansion Board - DM320002 ($72.00)

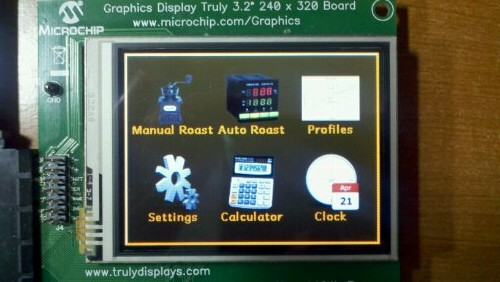

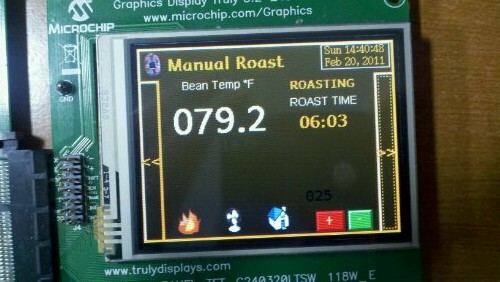

- Graphics PICtail Plus Daughter Board with 3.2 Display Kit - AC164127-3 ($154.99)

- Graphics LCD Controller PICtail Plus SSD1926 Board - AC164127-5 ($69.99)

- Graphics Display Truly 3.2" 240x320 Board with Touch Screen - AC1641217-4 ($99.99)

- 9440 Breadboard w/ 350pc Jumper Wire Kit - ($39.99)

- Prototype PICtail Plus Daughter Board - AC164126 ($20.00)

- MAX6675 Single Thermocouple Interface Board - ($21.50)

- Fast 100Mbps Ethernet PICtail Plus Daughter Board - AC164132 - ($49.99)

- 2 15A Relay board - ($16.00)

- DS1307 Breakout Board - ($14.95)

- DS3234 RTC Breakout Board - ($19.95)

- SHT1x Breakout Board - ($41.95)

- BMP085 Breakout Board - ($19.95)

- FT232R Breakout Board - ($14.95)

- SD Memory Card Breakout Board - ($9.95)

- MicroSD Memory Breakout Board - ($14.95)

- TechToys SSD1963 Eval Board w/ 7 inch 800x480 touch screen display - Bundle SSD1963EVK-R3B + 7" WVGA color TFT with Touch Panel ($119.00)

- Arduino Uno SMD - ($29.95)

- Arduino Mega 2560 - ($58.95)

- Arduino Ethernet Shield - ($45.95)

- Crib for Arduino - ($29.95)

- Ethernet Faceplate for Crib for Arduino - ($4.95)

- 30A Non-Invasive Current Sensor - ($9.95)

- Jack/Breakout for Current Sensor - ($2.45)

- Breadboard Power Supply - ($9.95)

- 10 pin ribbon crimp connector - Female (Qty 2) - ($1.00)

- 15 foot roll 10 wire ribbon cable - ($4.95)

- 100 pack 12" FF Jumper Wires - ($34.95)

- 100 pack 12" MF Jumper Wires - ($34.95)

- - ($xx.00)

Equipment/Tools:

- Aoyue 968 SMD/SMT Hot Air 3 in1 Repair & Rework Station - ($149.99)

- Aoyue 853A Quartz Infrared Preheating Station - ($105.00)

- Spring-Arm Magnifier Desk Lamp 5x7 5-Diopter - ($79.90)

- Open Workbench Logic Analyzer - ($xx.00)

- SMD Tweezers - Straight - ($3.95)

- SMD Tweezers - Curved - ($3.95)

- Brass Sponge & Base - ($9.95)

- - ($xx.00)

- - ($xx.00)

Parts/Components/Consumables:

- Lead Free No Clean Flux Solder Paste - ($16.00)

- RTH03 Sensor - ($xx.00)

- Mini Push Button Switches (Qty 7) - ($xx.00)

- Rotary Potentiometer (Linear) (Qty 2) - ($xx.00)

- - ($xx.00)

- - ($xx.00)

- - ($xx.00)

- - ($xx.00)

- - ($xx.00)

- - ($xx.00)

- - ($xx.00)

- - ($xx.00)

- More Coming Soon

Development Systems Investment: $946.07

Equipment/Tools Expense: $352.74

Prototype Parts/Components/Consumables Expense: $16.00

Total Expense (excluding taxes and shipping): $1,314.81

I will edit to update this list up here as I add equipment and explain more about the roaster in lower messages in the thread.

The final product will be PIC32 based but will occasionally use Arduino as a "verification aid" during development to ensure integrity of sensors and to offload inefficient processes off the main PIC32 until the code can be optimized. I prefer to make progress ensuring concepts work first rather than deal with efficiency and writing code from scratch to work in the PIC32 world. I seem to be pretty alone using some sensors connected to the PIC32 and quite alone using one to control a coffee roaster so this seems like the best compromise. Arduino has a lot of sample code and schematics to prove concepts (and communicate them via I2C, SPI, or UART/serial to the PIC32) and a large community of people controlling coffee roasters w/ Arduino. Once each of my ideas are proven sound I'll adjust voltages/wiring to connect directly to a PIC32 and figure out how to write the new code on PIC32 knowing it works with Arduino properly.